3-(Methacryloxy) propylmethyldimethoxysilane

| Chemical Name: | 3-(Methacryloxy) propylmethyldimethoxysilane |

| Alias: | Methacrylic acid oxypropylmethyldimethoxy silane |

| Product Category: | CAS 14513-34-9 Acyloxy Silanes | Silanes |

| CAS NO.: | 14513-34-9 |

| Formula: | CH3CCH2COO(CH2)SiCH3(OC2H5)2 |

| EINECS: | 238-518-6 |

| Molecular Weight: | 232.35 |

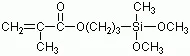

| Molecular Formula: |  |

| Boiling Point: | 65°C/0.13KPa |

| Density: | 1.020~1.060 (ρ20)g/cm3 |

3-(Methacryloxy) propylmethyldimethoxysilane Description

3-(Methacryloyloxy)propylmethyldimethoxysilane is suitable for polyethylene and copolymers of various complex shapes and all densities; it is suitable for large processing tolerance, filled composites, etc., and has high service temperature, excellent pressure cracking resistance, abrasion resistance and impact resistance; it can be grafted to the main chain of the polymer and thus modify other polymers, such as polyethylene, so that the side chain carries ester groups with the product, which can serve as the active point of warm-water crosslinking.

| Product Name | 3-(Methacryloyloxy) propylmethyldimethoxysilane |

| Boiling point | 65°C/0.13KPa |

| Density | 1.020~1.060 (ρ20)g/cm3 |

| Refractive index | 1.425~1.435 (n25D) |

| Applications | Glass Fiber | Adhesives | Resins | Fillers |

| Package | 5kg/drum, 20kg/ctn. Sealed and stored in a cool, dry and ventilated place, moisture-proof and water-proof, away from fire and heat source. |

| Usage |

|

Packaging Specifications

Jessica G.

Get in touch to Get

- Quick and helpful reply within 8 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.

3-(Methacryloxy) propylmethyldimethoxysilane: Guide

3-(Methacryloxy) propylmethyldimethoxysilane is a methacryl-functional silane; it is a clear, light and heat sensitive liquid with a faintly sweet odour.

It is used as adhesion promoter at organic/inorgainc interfaces, as surface modifier (e.g. imparting water repellency, organophilic surface adjustment) or as crosslinking of polymers).

It is used as a coupling agent to improve the physical and electrical properties of glass-reinforced and mineral-filled thermosetting resins under exposure to heat and/or moisture.3-(Methacryloxy) propylmethyldimethoxysilane is typically employed as a blend additive in resin systems that cure via a free radical mechanism (e.g. polyester, acrylic) and in filled or reinforced thermoplastic polymers, including polyolefins and polyurethanes.It is also used to functionalize resins via radical initiated processes-copolymerization or grafting – and to modify surfaces.

It is used as adhesion promoter at organic/inorgainc interfaces, as surface modifier (e.g. imparting water repellency, organophilic surface adjustment) or as crosslinking of polymers).

It is used as a coupling agent to improve the physical and electrical properties of glass-reinforced and mineral-filled thermosetting resins under exposure to heat and/or moisture.3-(Methacryloxy) propylmethyldimethoxysilane is typically employed as a blend additive in resin systems that cure via a free radical mechanism (e.g. polyester, acrylic) and in filled or reinforced thermoplastic polymers, including polyolefins and polyurethanes.It is also used to functionalize resins via radical initiated processes-copolymerization or grafting – and to modify surfaces.