Fumed Silica

| Chemical Name: | Fumed Silica |

| Alias: | Fumed Silica, Silicon Dioxide, Fumed White Carbon Black |

| Product Category: | White Carbon Black – Product |

| CAS No.: | 7631-86-9 |

| Classification: | Silicon Dioxide |

| Grade Standard: | Industrial Grade |

| HS Code: | 2811229000 |

| Quality: | First Class |

| Transport Package: | 10kg/Bag |

Fumed Silica Describe

Fumed Silica (CAS No. 7631-86-9), also known as fumed white carbon black, is a high-tech ultrafine inorganic material with exceptional purity and performance. Appearing as a white, non-toxic, tasteless, and pollution-free fluffy powder, it features a small particle size, large specific surface area, strong adsorption capacity, high chemical stability, and excellent dispersion.

Key Features & Benefits:

✅ Reinforcement & Thickening: Enhances mechanical strength in rubber, plastics, and coatings.

✅ Thixotropy & Stability: Improves viscosity control and anti-settling properties in inks, paints, and adhesives.

✅ Heat & Chemical Resistance: Ensures durability in demanding industrial applications.

✅ Versatile Applications: Used in rubber, plastics, coatings, inks, cosmetics, pharmaceuticals, petrochemicals, environmental protection, and insulation materials.

With its unique physical and chemical properties, nano-silica plays a crucial role in enhancing product performance, optimizing formulations, and supporting advancements in various industries.

| Item No | Index | Measured Value |

| Appearance | White powder | Compliance index |

| Specific surface area of nitrogen adsorption m²/g | 200±10 | 200 |

| Sio2- content | >99.8 | 99.9% |

| Ph | 3.7-4.5 | 4.19 |

| Volatile matter % at 105 ºC | ≤3.0 | 0.82 |

| Tamping density g/dm³ | 30-60 | 31 |

| Sieve residue(45μm) mg/kg | ≤250 | 19.93 |

| Model No | RS-GE200 |

| Appearance | white powder |

| Grade | First class |

| HS code | 2811229000 |

| Free sample | Support |

| Packing | 20’GP:10kg/bag;200kg/pallet;2mt/fcl 40’GP:10kg/bag;200kg/pallet;4mt/fcl |

| Delivery time | 5-7 days after payment |

| Production Capacity | 5000mt/year |

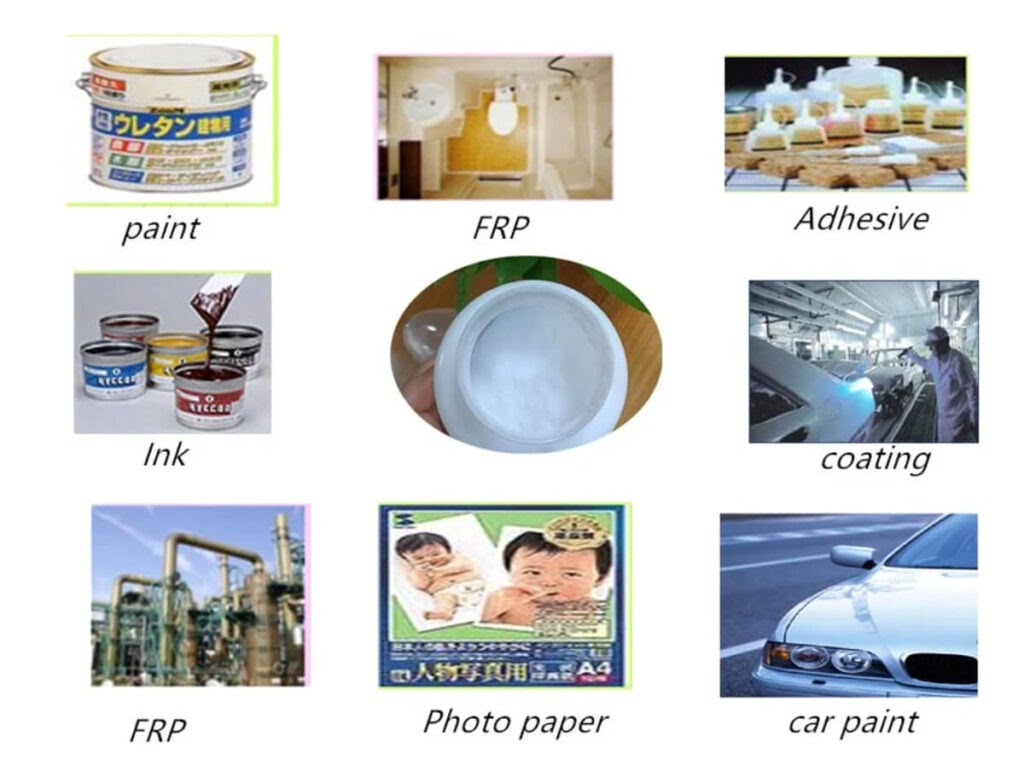

Applications of Fumed Silica

Fumed silica is widely used in industrial and consumer products, but proper handling is essential due to potential health risks.

Key Applications:

✔ Resin Additives & Pharmaceuticals – Used in medicine, food, and specialty chemicals.

✔ Rubber & Adhesives – Enhances sealants, silica gel, adhesives, and tile grout.

✔ Paints & Coatings – Improves viscosity and durability in paints, coatings, and UPR.

✔ Electronics – Key in CMP suspensions for semiconductor processing.

✔ Printing – Enhances digital photo paper quality.

Fumed silica offers reinforcement, thickening, and stability across industries but requires safe handling.

Factory Introduction

Packaging Specifications

Jessica G.

Get the Latest Pricing and Information

- Quick and helpful reply within 8 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.

Fumed Silica : Guide

Silica includes Precipitated Silica, Fumed Silica, Ultrafine Silica Gels, and Synthetic Silicates, widely used for reinforcement, thickening, and rheology control.

Main Benefits:

✔ Strength & Durability – Improves tensile strength, toughness, and impact resistance.

✔ Thickening & Flow Control – Enhances viscosity, stability, and application performance.

✔ Anti-Caking & Free Flow – Prevents clumping in powders.

✔ Sag & Drip Resistance – Ensures smooth application in coatings and adhesives.

✔ Heat & Thermal Stability – Provides insulation and heat resistance.

Used in coatings, adhesives, rubber, plastics, and pharmaceuticals, silica enhances performance and stability across industries.

✔ Thickening & Flow Control – Enhances viscosity, stability, and application performance.

✔ Anti-Caking & Free Flow – Prevents clumping in powders.

✔ Sag & Drip Resistance – Ensures smooth application in coatings and adhesives.

✔ Heat & Thermal Stability – Provides insulation and heat resistance.