CYS-101 Carboxy-Terminated Silicone Fluid

CYS-101 Carboxy-Terminated Silicone Fluid (CAS 851486-70-9) is a high-performance carboxy-terminated PDMS from Silico®. With reactive end groups, it offers good compatibility, water resistance, and crosslinking ability, making it suitable for leather, textiles, polymers, coatings, and surface treatments.

Product Introduction:

CYS-101 Carboxy-Terminated Silicone Fluid (CAS 851486-70-9) is a highly reactive carboxy-functional silicone Fluid featuring carboxyl-terminated polydimethylsiloxane (PDMS) chains. Manufactured by Silico®, this specialty silicone fluid is engineered for advanced surface modification, polymer enhancement, and hydrophobic treatment across multiple industries including leather processing, textile finishing, polymer blending, and surface coating.

Technical Specifications

| Attribute | Description / Typical Value |

|---|---|

| INCI Name | Carboxy-terminated polydimethylsiloxane |

| CAS Number | 851486-70-9 |

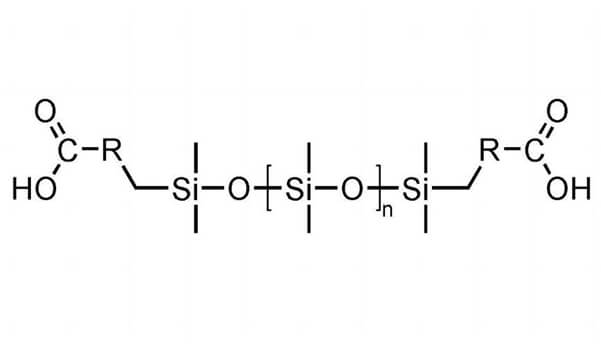

| Chemical Structure | –COOH terminated PDMS polymer chain |

| Functional Group | Carboxyl (–COOH) |

| Equivalent Products | Comparable to Dowsil™ BY 16-750 or similar |

| Appearance | Transparent to slightly hazy, pale yellow viscous liquid |

| Viscosity @ 25°C | 500 – 2,000 cSt (adjustable upon request) |

| Density @ 25°C | Approx. 0.98 g/cm³ |

| Refractive Index @ 25°C | 1.410 – 1.420 |

| Carboxy Content | Customizable based on application needs |

| Solubility | Soluble in alcohols; emulsifiable in water |

| Thermal & Chemical Stability | Stable under acid, alkali, and shear conditions; non-yellowing |

Key Benefits & Performance Features

Reactive Carboxyl Terminals

Offers excellent reactivity for chemical grafting, crosslinking, and chain extension in polyester and polyamide formulations.Enhanced Water Repellency

Significantly improves hydrophobicity in chrome-tanned leather and other natural substrates.Surface Modification

Provides smoothness, anti-stick, anti-blocking, and abrasion resistance in coatings, rubbers, and plastics.Compatibility with Organic Systems

Enhances the dispersion of pigments, fillers, and additives in thermoplastics and organic matrices.Stable Under Harsh Conditions

Acid- and alkali-resistant; remains stable under high shear and does not yellow over time.Emulsifiable in Aqueous Systems

Easily formulated into water-based emulsions for textile or leather softening applications.

Common Industrial Applications

| Sector | Use Case Description |

|---|---|

| Leather Treatment | Increases water repellency and stain resistance in leather finishing |

| Textile Finishing | Imparts softness, hydrophilicity, and anti-static properties |

| Polymer Modification | Acts as a chain extender or crosslinker for polyamide, PET, TPU, or PU systems |

| Pigment/Filler Surface Treatment | Improves wetting, dispersion, and bonding with organic phases |

| Industrial Coatings | Improves scratch resistance, slip, and surface durability |

Packaging Options:

We offer flexible packaging for both R&D and bulk industrial use:

1 kg & 5 kg HDPE bottles (sample/lab-scale)

25 kg pails & 200 kg drums (industrial production)

1000 kg IBC totes available on request

Custom viscosity grades and formulations available under Silico® brand lines

All technical data provided is based on current knowledge and experience. Users must test product suitability for intended applications.

No warranties are expressed or implied. Silico® assumes no liability for incidental or consequential damages.

Jessica G.

Get in touch to Get

- Quick and helpful reply within 8 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.